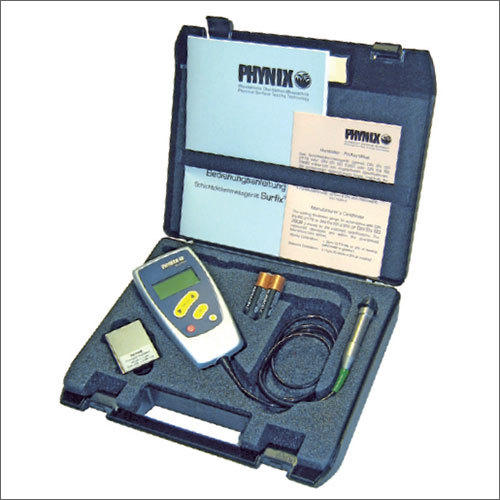

Digital Coating

Price 75000 INR/ Unit

Digital Coating Specification

- Frequency

- 50 Hertz (HZ)

- Usage

- Industrial, Automobile

- Material

- Metal

- Grade

- Industrial

- Application

- Other

- Color

- Blue

Digital Coating Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 5 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Digital Coating

Utilizing on the ability of our adroit staff, we are persuaded in introducing a superior quality items to our significant customers. Here our firm is giving that is made by using qualitative required materials with the help of latest technology. It is widely utilized coatings industry for measuring dry film thickness. This item is appreciated in the market because of its high quality and superb durability. can be avail from us at fixed price rate.

Measuring principle

- Magnetic induction principle (F-Mode) for ferrous metals

- Eddy-current principle (N-Mode) for non-ferrous metalsi

- FN-Mode for all metals

- Rangei 0 - 1500 m (0 -60 mils)

- Accuracyi +/- (1 m / 0.04 milsi 1 % of reading)

- Resolutioni 0.1 m / 0.004 mils ori 0.2i of reading

- Displayi iBacklight, 4-digit alphanumeric, height 10 mm (0.4 )

- Calibrationi iFactoryi zero- and foil-calibration Offset-function: addition/subtraction of a constant value

- Memoryi Max. 200 readings

- Statistics Programi Number of readings, mean value, standard deviation max. and min. readingi

- Data Output Infrared interface

- Operating Temperature 0 C to + 50 C / 32 F to 122 F

Surface Temperature

- -15 C to + 60 C / 5 F to 140 F (standard)

- -15 C to + 150 C / 5 F to 302 F (with optional foot)

Power 2 AA, 1.5 V

Dimensionsi 137 mm x 66 mm x 23 mm (5.4i x 2.6i x 0.9 )

Weighti 205 g (7.2 oz) incl batteries

Protection Classi IP 52 (proof against dust and dripping water)

Standardsi DIN, ISO, ASTM, BSi

Measuring Limits

- Minimum Radius for Convex Surfaces 1.5 mm (0.06 )

- Minimum Radius for Concave Surfaces 5 mm (0.2 )

- Minimum Headroom 100 mm (4 )

- Minimum 5 mm x 5 mm Measuring Area (0.2i x 0.2 )

- Minimum Substratei

- Thickness - F 0.2 mm (8 mils) Minimum Substratei

- Thickness - N 50 m (2 milsi

i

Advanced Industrial Coating Technology

Our digital coating solutions leverage cutting-edge manufacturing methods to ensure strong adhesion and long-lasting protection for metal surfaces. Specifically engineered for industrial and automotive sectors, these coatings help extend the service life of critical components and parts, while maintaining their aesthetic appeal. The 50 Hz frequency operation enables seamless application across a variety of environments, offering flexibility and enhanced surface coverage.

Reliability You Can Trust

As a trusted Indian exporter, manufacturer, and supplier, our digital coatings are meticulously tested to assure consistent quality and performance. Our products are designed with both protective and visual attributes in mind, making them suitable for demanding standards across the globe. Count on us for coatings that support your manufacturing, maintenance, and refurbishment projects.

FAQs of Digital Coating:

Q: How is the digital coating applied to industrial and automobile components?

A: The digital coating is applied using specialized equipment capable of handling 50 Hz frequency, ensuring an even and durable finish on metal surfaces. The process can involve spraying, dipping, or electrostatic methods, depending on the component and required coverage.Q: What is the main benefit of using this digital coating for industrial and automobile purposes?

A: The primary benefit is enhanced protection against corrosion, wear, and environmental factors. The coating also improves the visual appeal with its blue finish, while ensuring robust adhesion and long-term durability for metal parts.Q: When should digital coating be considered for your equipment?

A: Digital coating is recommended during the manufacturing of new equipment or when refurbishing existing industrial and automobile parts to extend their lifespan and maintain functionality. It is ideal whenever top-tier protection and surface longevity are required.Q: Where can this coating be used effectively?

A: This digital coating is suitable for diverse industrial settings including factories, workshops, and automobile manufacturing plants. Its an excellent choice for any metal components exposed to harsh conditions, both indoors and outdoors.Q: What is the process involved in manufacturing the digital coating?

A: The coating is produced using advanced metal processing techniques in India, ensuring quality and conformity to industrial standards. Automated systems regulate the application at 50 Hz frequency, achieving uniform coverage and optimal adhesion.Q: How does this digital coating improve the usage of automotive and industrial products?

A: By forming a protective barrier, the coating reduces maintenance needs, prevents rust and degradation, and supports smoother operation of machinery or vehicles. Its resilient composition ensures reliability even in challenging conditions.Q: What makes your company a preferred exporter and supplier of digital coatings in India?

A: Our commitment to quality, timely delivery, and a wide product range positions us as a reliable partner. We adhere to strict manufacturing standards, cater to bulk and custom orders, and ensure tailored solutions for diverse industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry